Salsify Network Webinar: Key Connections for 2026 Success → March 17th | 11:00 AM ET

What Is PXM?

Solutions

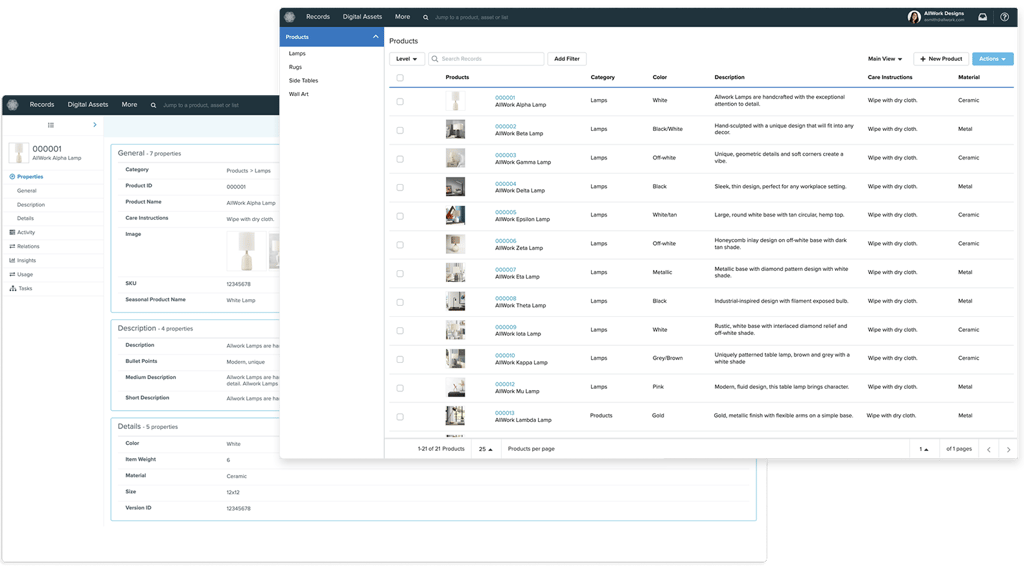

Products

PIM

Manage all product content in one central system of record.

Syndication

Easily syndicate product content to every consumer touch point.

Enhanced Content

Enrich product pages with below-the-fold content and rich media.

Intelligence Suite

Bring AI-powered capabilities directly into your Salsify workflows.

Grocery Accelerator

Leverage the first-ever category-wide PXM accelerator in the grocery industry.

GDSN Data Pool

Synchronize standard supply chain, marketing, and ecommerce attributes globally.

Digital Shelf Analytics

Continuously optimize your organization’s product content syndication.

Catalog Sites

Share secure, on-brand, and always up-to-date digital product catalogs.

Automation and AI

Automate business processes and enhance Salsify workflows with AI.

PXM Platform, Integrations, and APIs

Integrate the PXM platform with the rest of your enterprise systems architecture.

Supplier Onboarding

Accelerate supplier onboarding while ensuring your schema requirements are met.

Product Listing

Sell products faster with Product Listing.

Content Enrichment

Increase online conversions with Content Enrichment.

Automation

Save time and increase operational efficiency with retail automation.

SXM Platform, Integrations, and APIs

Integrate the SXM platform with the rest of your enterprise systems architecture.

Syndication Network

Automate how you exchange product content data to the digital shelf.

Enhanced Content Network

Turn product pages into product experiences with Enhanced Content.

Commerce Platform Integrations

Create winning product experiences everywhere shoppers are, including on owned sites.

GDSN Data Pool

Synchronize standard supply chain, marketing, and ecommerce attributes globally.

Open Catalog

Connect to the digital shelf faster with an open, standardized, and free product catalog.

Partners

Resources

Resources

Resource Library

Explore our ecommerce resources to get everything you need to win on the digital shelf.

Blog

Read our blog to get actionable insights for navigating changing markets and industry demands.

Webinars

Watch our on-demand ecommerce webinars to gain expert advice and tips from our community of industry leaders.

Customer Blog

Gain the latest tips, industry trends, and actionable ecommerce insights.

Knowledge Base

Investigate our knowledge base to build your Salsify skills and understanding.

API

Examine our comprehensive API and webhook guides to start working with Salsify quickly.

Our latest report shares shoppers' fresh insights on buying behavior, loyalty, AI trust, and more.

.svg)